D-LINE

REVERSE VENDING MACHINE

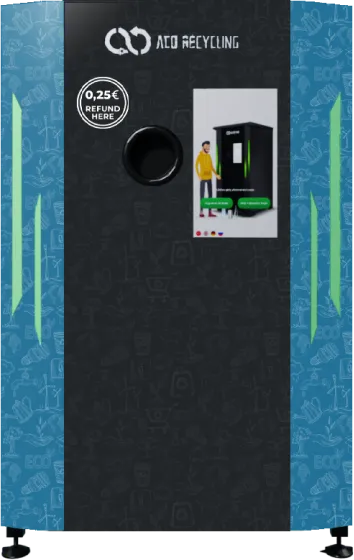

ACO D-LINE REVERSE VENDING MACHINE, A COMPACT YET REMARKABLY EFFICIENT SOLUTION FOR RECYCLING NEEDS. THIS MACHINE IS AN IDEAL CHOICE FOR SUPERMARKETS AND RETAILERS LOOKING FOR BACKDOOR SOLUTIONS THAT CONSERVE FLOOR SPACE WITHOUT COMPROMISING ON CAPACITY OR TECHNOLOGY. DESPITE ITS SMALLER FOOTPRINT, ACO D-LINE IS EQUIPPED WITH THE SAME ADVANCED FEATURES AND RECOGNITION TECHNOLOGIES AS THE RENOWNED K-3 MODEL. THIS INCLUDES HIGH ACCURACY IN MATERIAL SORTING AND A USER-FRIENDLY INTERFACE, ENSURING SEAMLESS OPERATION. WHAT SETS THE D-LINE APART IS ITS EXTRAORDINARY CAPACITY, MADE POSSIBLE THROUGH OPTIONAL MODULES LIKE CRUSHERS, COMPACTORS, OR SHREDDERS. THESE ADD-ONS ENABLE THE MACHINE TO HANDLE UP TO 9,000 UNITS, MAKING IT A POWERHOUSE IN TERMS OF COLLECTION CAPACITY.

60 ITEMS PROCESSED PER

MINUTE.

EQUIPPED WITH A THERMAL

PRINTER FOR VOUCHERS.

LOYALTY CARD INTEGRATION

CAPABILITY.

4G ROUTER AND LAN

CONNECTIVITY.

ONE-PHASE AND THREE-PHASE OPTIONS VARY BASED ON

SUB-MODELS AND ACO MODULES.

PLUG & PLAY FUNCTIONALITY.

API INTEGRATION FOR EXTERNAL

APPS.

OPERATIONAL BOTH ONLINE

AND OFFLINE.

CONTINUOUS LEARNING TECH

WITH PERIODIC SYSTEM

UPDATES.

GLOBALLY ADAPTABLE

ELECTRICAL SETUP.

MODULES

EACH MODULE IS DESIGNED TO ENHANCE THE FUNCTIONALITY OF ACO RECYCLING REVERSE VENDING MACHINES.

IN-DEPTH LOOK AT THE DIVERSE MODULES AVAILABLE FOR ACO RECYCLING REVERSE VENDING MACHINES, HIGHLIGHTING HOW THEY ENHANCE MACHINE FUNCTIONALITY AND ADAPT TO DIFFERENT DEPOSIT RETURN SYSTEMS. EACH MODULE’S ADVANCED FEATURES AND CAPABILITIES ARE DETAILED, DEMONSTRATING THEIR IMPACT ON MACHINE PERFORMANCE AND EFFICIENCY. EXPLORE THIS SECTION FOR INSIGHTS INTO THE TECHNOLOGICAL INNOVATION AND FLEXIBILITY THAT ACO RECYCLING BRINGS TO DEPOSIT RETURN SYSTEM SOLUTIONS.

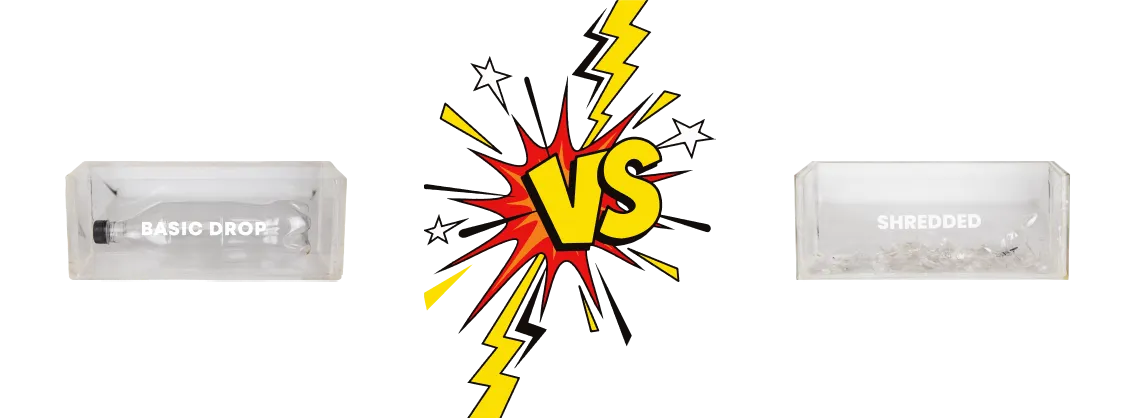

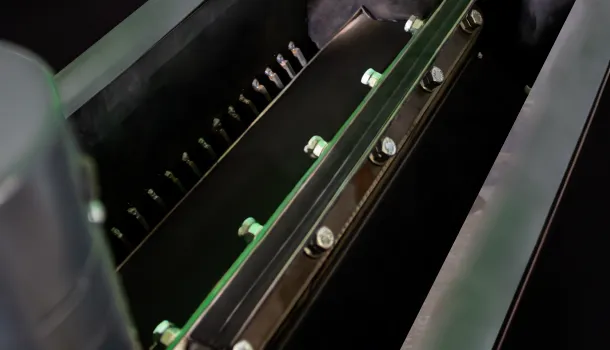

SHREDDER

ACO SHREDDER MODULE SIGNIFICANTLY BOOST THE INTERNAL CAPACITY OF REVERSE VENDING MACHINES, INCREASING IT UP TO 2.5 TIMES MORE THAN STANDARD MODELS. THESE MODULES EFFICIENTLY SHRED BOTH ALUMINUM/METAL AND PLASTIC MATERIALS, ENHANCING THE QUALITY OF THE MATERIAL FOR RECYCLING FACILITIES. THIS FEATURE STREAMLINES THE RECYCLING PROCESS, REDUCING THE NUMBER OF STEPS REQUIRED AND FACILITATING MORE EFFICIENT RECYCLING OPERATIONS.

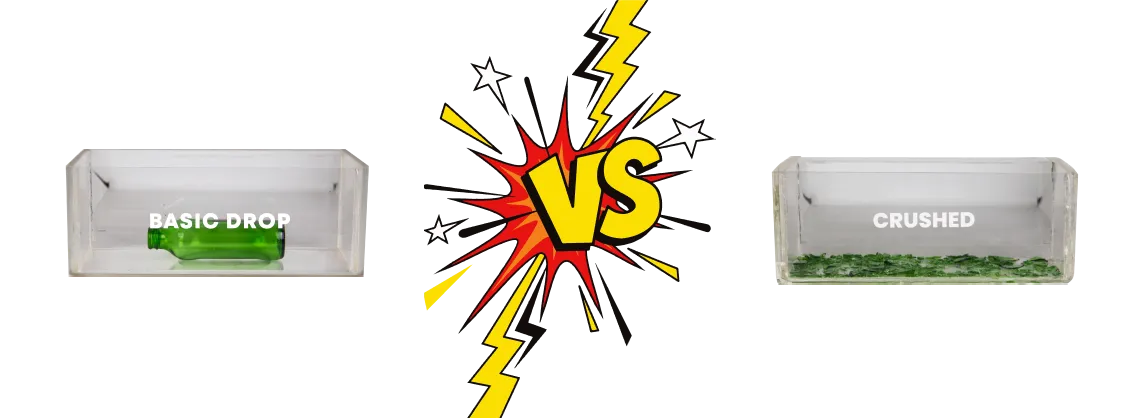

CRUSHER

ACO CRUSHER MODULE IS SPECIFICALLY DESIGNED FOR GLASS PROCESSING IN REVERSE VENDING MACHINES. IT EFFECTIVELY BREAKS DOWN GLASS WITH MINIMAL DUST GENERATION, SAFEGUARDING BOTH EFFICIENCY AND HEALTH STANDARDS. THIS MODULE IS IDEAL FOR GLASS RECYCLING COMPANIES, AS IT PRODUCES GLASS FRAGMENTS OF OPTIMAL SIZE FOR RECYCLING, WHILE MINIMIZING GLASS DUST, THEREBY PRESERVING PROFITABILITY AND ENSURING A SAFER RECYCLING ENVIRONMENT.

COMPACTION

ACO COMPACTION MODULE, ROBUST AND BUILT FOR LONGEVITY, ENHANCES THE EFFICIENCY OF REVERSE VENDING MACHINES. IT COMPACTS PLASTIC AND ALUMINUM/STEEL CANS AT HIGH SPEEDS, DOUBLING THE CAPACITY COMPARED TO STANDARD MACHINES. THIS MODULE ENSURES SUPERIOR OUTPUT QUALITY, OFFERING A DURABLE AND HIGH-PERFORMING SOLUTION FOR RECYCLING NEEDS.

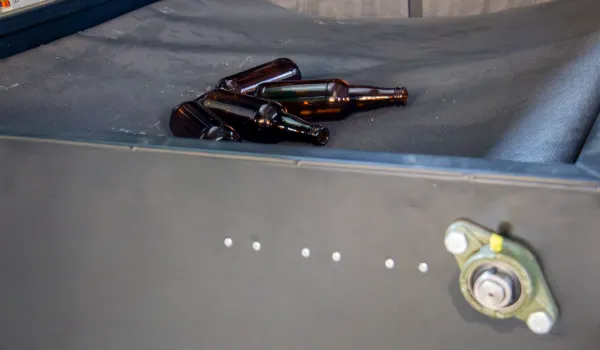

S-DROP

ACO S-DROP MODULE IS DESIGNED FOR EFFICIENT COLLECTION OF REFILLABLE GLASS BOTTLES, ENSURING THEY REMAIN FREE FROM DAMAGES OR MICRO-CRACKS. THIS TECHNOLOGY IS PARTICULARLY EFFECTIVE FOR RB-TYPE BOTTLES, MAXIMIZING THEIR LIFESPAN FOR REUSE. WITH A HIGH SAFETY RATE OF 1 DAMAGE IN 1000 BOTTLES, ACO S-DROP STANDS OUT AS A RELIABLE SOLUTION FOR COLLECTING GLASS BOTTLES AT RETURN POINTS, MAKING IT AN ESSENTIAL COMPONENT FOR SUSTAINABLE RECYCLING OPERATIONS.

FOR ILLUSTRATIVE PURPOSES, WE’VE USED AN IMAGE OF A BROKEN GLASS BOTTLE TO HIGHLIGHT THE DISTINCTION BETWEEN OUR BASIC DROP AND THE S-DROP MODULE. WHILE THE BASIC DROP TYPICALLY DOES NOT BREAK GLASS, THIS COMPARISON HELPS TO CLEARLY DEMONSTRATE THE S-DROP’S ABILITY TO PROTECT BOTTLES FROM MICRO-CRACKS AND ENSURE THEIR INTEGRITY.

DIMENSIONS

UNDERSTANDING THE DIMENSIONS OF THE D-LINE REVERSE VENDING MACHINE IS KEY FOR SEAMLESS INSTALLATION AND COST-EFFECTIVE SHIPMENT PLANNING. OUR DIMENSIONS AND DETAILS SECTION OFFERS VITAL INFORMATION ON THE MACHINE’S SIZE, INCLUDING LENGTH, WIDTH, AND HEIGHT, ALONG WITH ITS FOOTPRINT IN SQUARE METERS. ADDITIONALLY, WE PROVIDE INSIGHTS INTO SHIPPING OPTIONS AND CONTAINER FITTING FOR SEA TRANSPORT, HELPING YOU MAKE INFORMED DECISIONS FOR EFFICIENT LOGISTICS AND SPACE MANAGEMENT. EXPLORE THIS SECTION TO EQUIP YOURSELF WITH ESSENTIAL KNOWLEDGE FOR INTEGRATING THE D-LINE INTO YOUR SPACE.

SIZES

LENGTH

4.422 M

174.09 INCH

WIDTH

1.26 M

49.6 INCH

HEIGHT

2.04 M

80.31 INCH

SHIPPING OPTIONS

SEA

20 S

40 S

40 HC

1 UNIT

3 UNIT

3 UNIT

AIR

VARIES

VARIES

VARIES

VARIES

VARIES

VARIES

LAND

MA

DKK

AKR

3 UNIT

3 UNIT

2+2

FOOTPRINT

5.57M²

![]() PLEASE NOTE THAT THE DIMENSIONS AND SPECIFICATIONS LISTED ARE SUBJECT TO VARIATION. FOR THE MOST ACCURATE AND UP-TO-DATE INFORMATION, WE ENCOURAGE YOU TO CONTACT ACO RECYCLING DIRECTLY FOR FINAL CONFIRMATION.

PLEASE NOTE THAT THE DIMENSIONS AND SPECIFICATIONS LISTED ARE SUBJECT TO VARIATION. FOR THE MOST ACCURATE AND UP-TO-DATE INFORMATION, WE ENCOURAGE YOU TO CONTACT ACO RECYCLING DIRECTLY FOR FINAL CONFIRMATION.

HOW TO MOVE

MOVING THE D-LINE REVERSE VENDING MACHINE IS DESIGNED FOR EASE AND SAFETY. ITS STRUCTURE ACCOMMODATES DIRECT USE WITH FORKLIFTS, ELIMINATING THE NEED FOR ADDITIONAL PALLETS. THIS FEATURE ENSURES SECURE AND STRAIGHTFORWARD LIFTING AND TRANSPORTATION. ADDITIONALLY, THE MACHINE INCLUDES AN INTEGRATED SYSTEM COMPATIBLE WITH JIGGERS OR PALLET JACKS, FACILITATING CONVENIENT MANEUVERABILITY WITHIN YOUR SPACE. THESE USER-FRIENDLY MOVING SOLUTIONS UNDERSCORE THE D-LINE’S PRACTICAL DESIGN, EMPHASIZING EASE OF RELOCATION AND ADAPTABILITY TO VARIOUS OPERATIONAL ENVIRONMENTS.

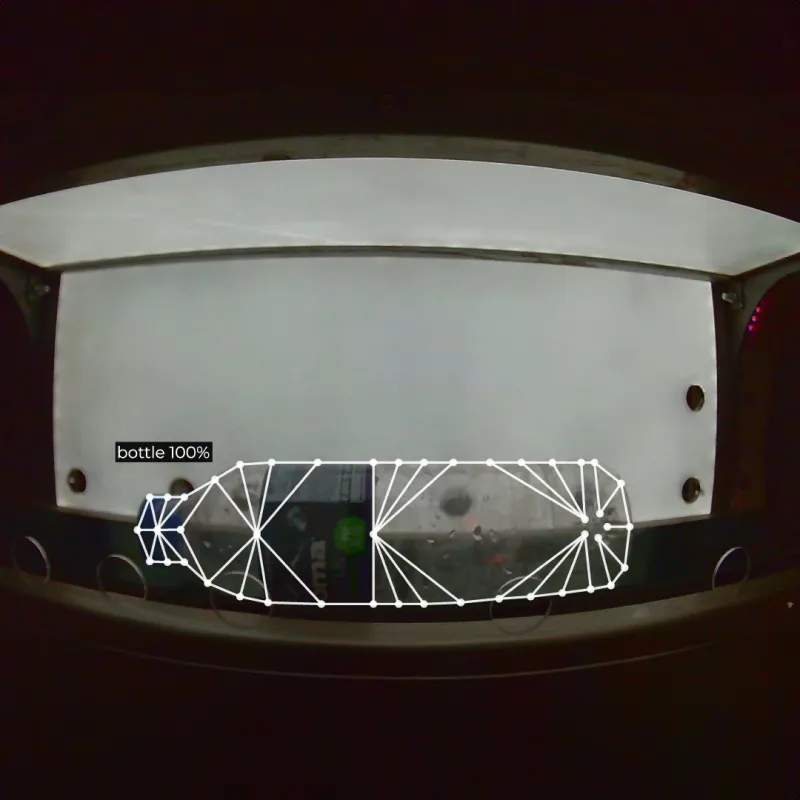

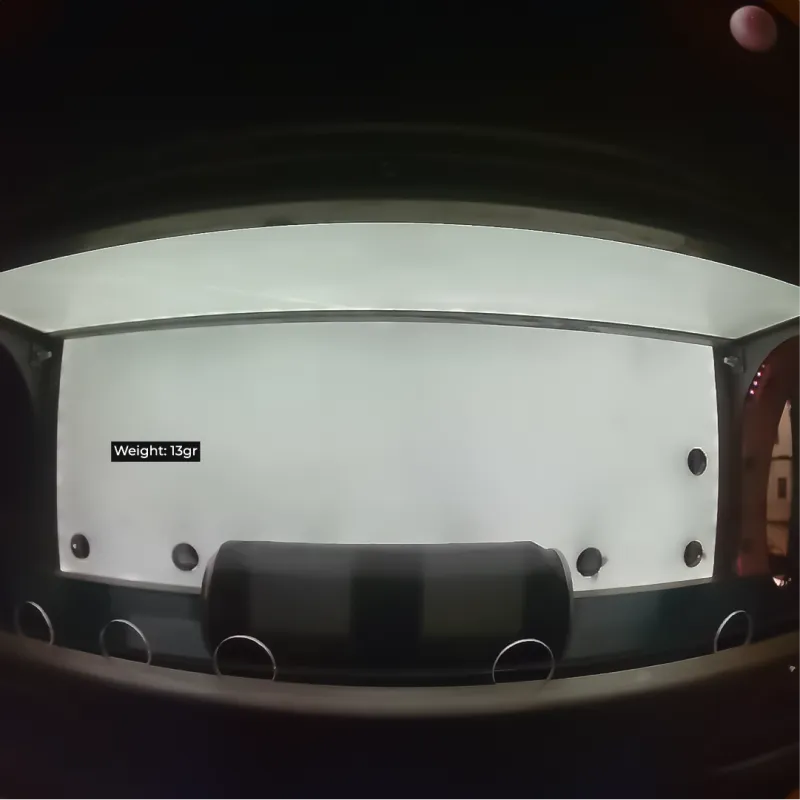

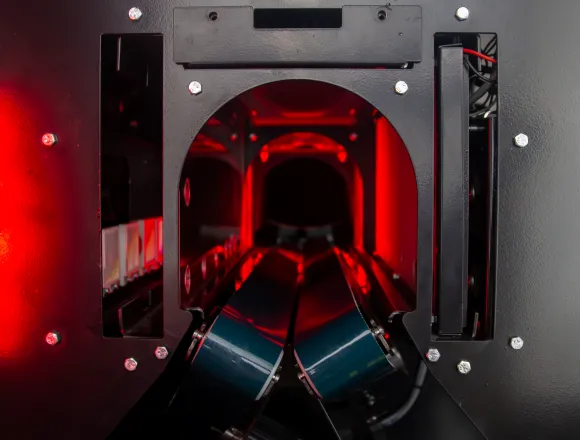

ACO RECOGNITION TECHS

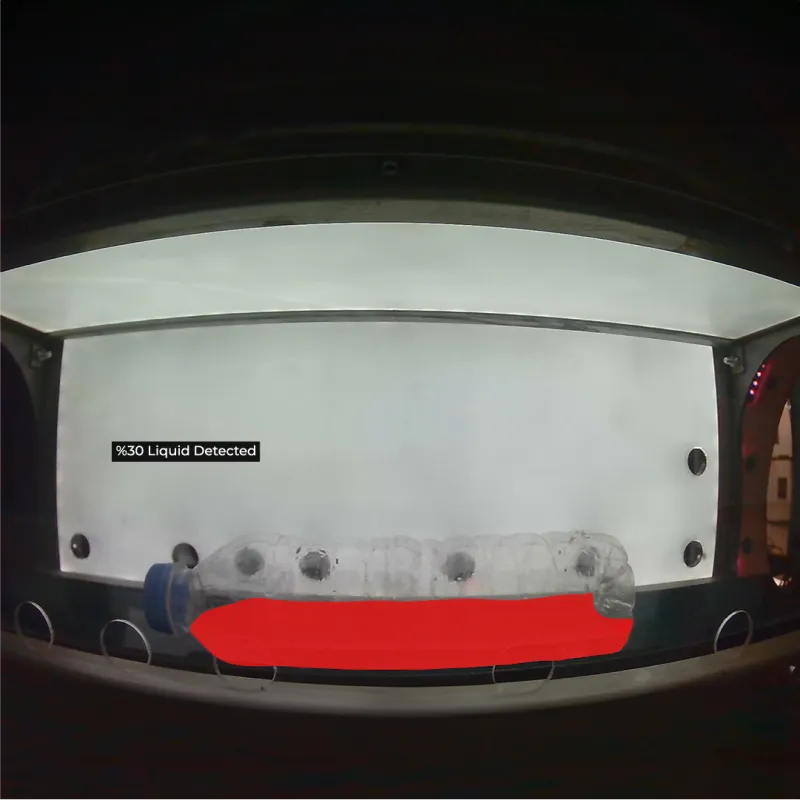

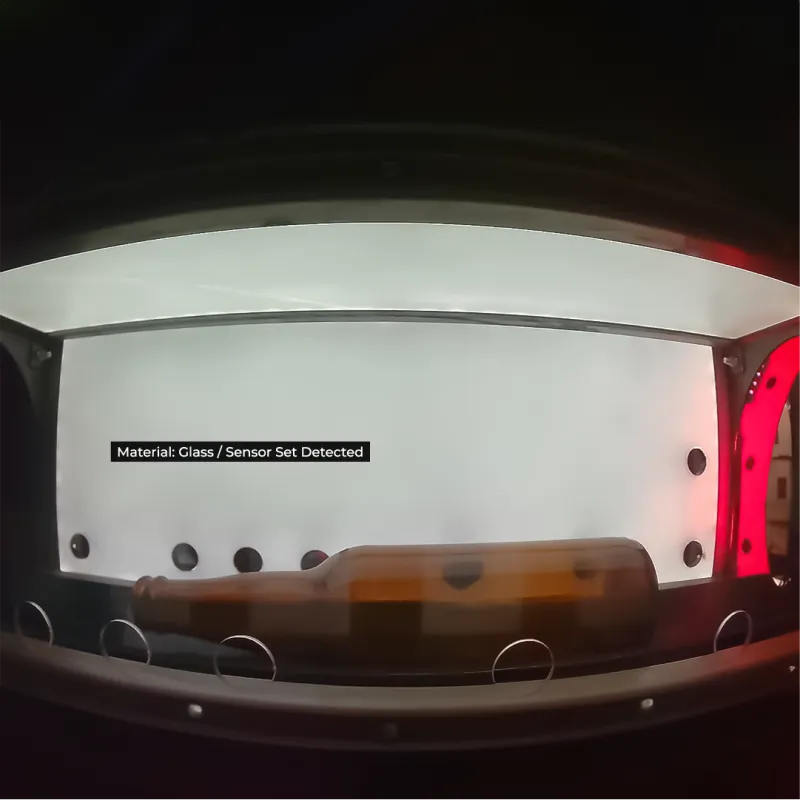

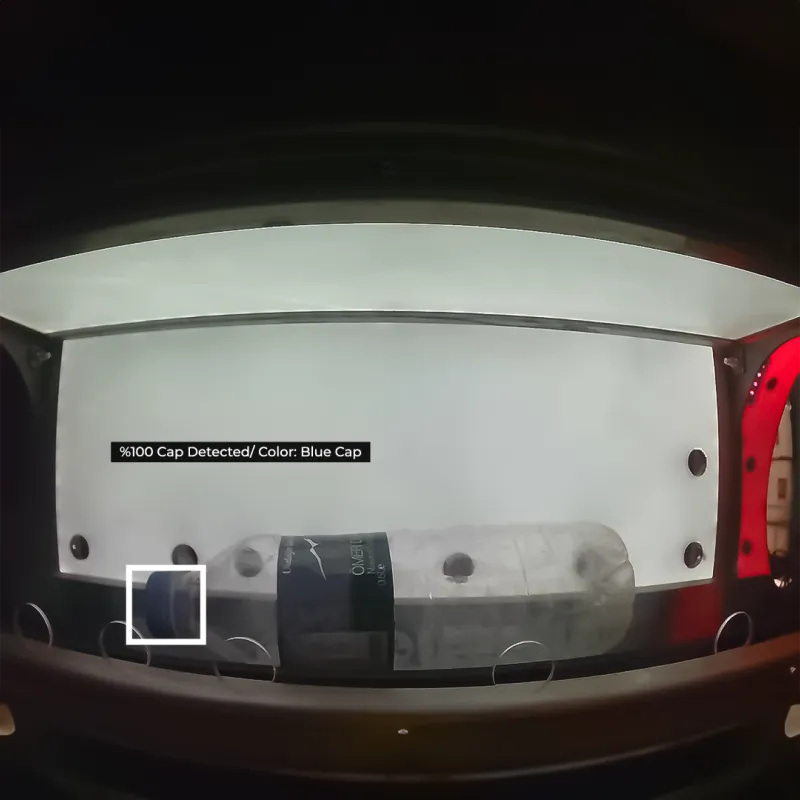

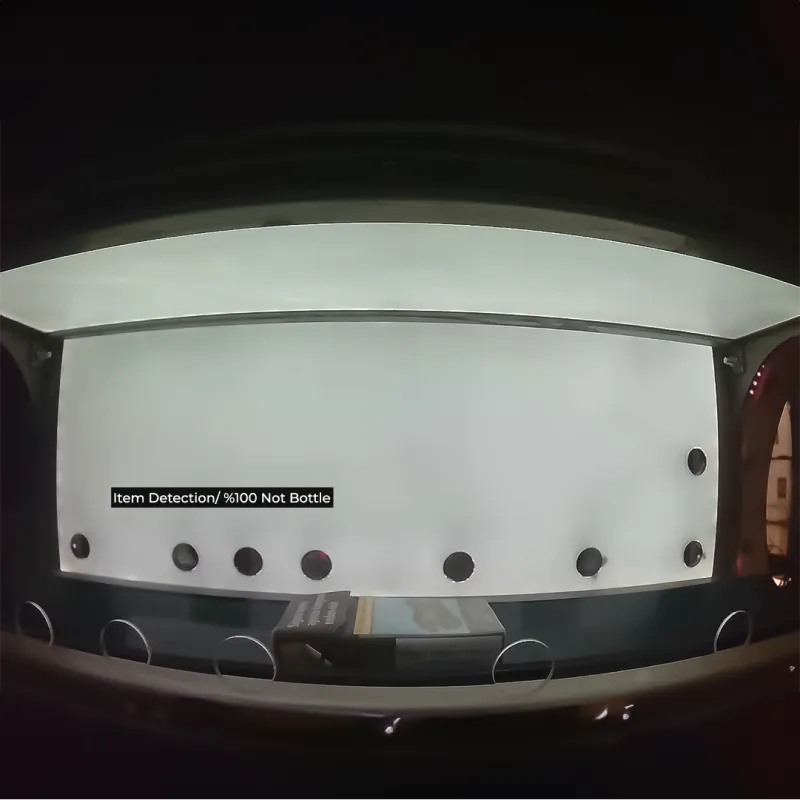

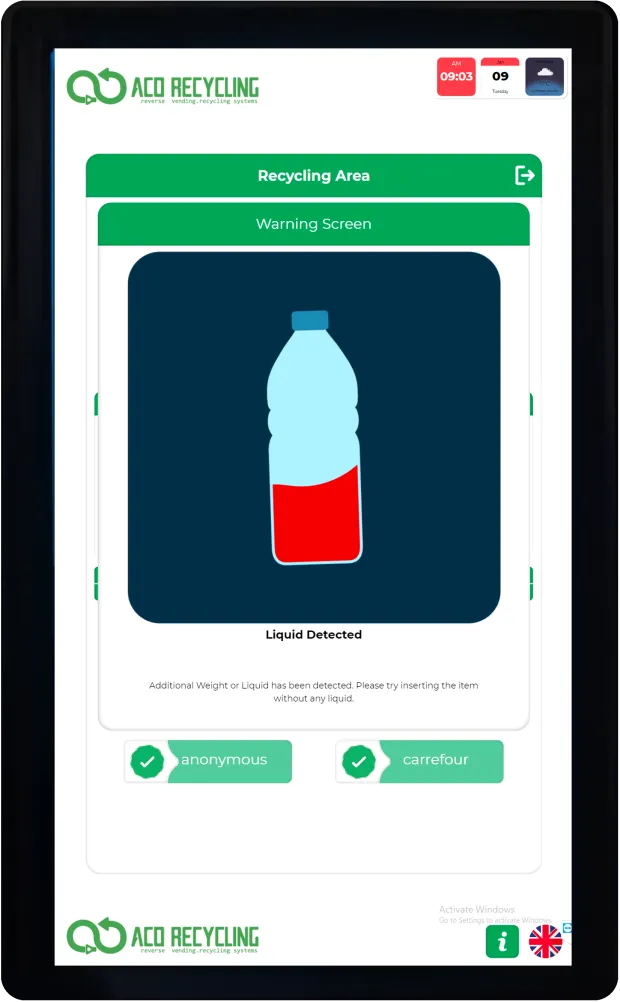

ACO RECYCLING SETS ITSELF APART IN THE REVERSE VENDING MACHINE (RVM) INDUSTRY WITH ITS ADVANCED ACO RECOGNITION TECHS. THESE IN-HOUSE DEVELOPED, MULTI-LAYERED RECOGNITION TECHNOLOGIES OFFER UNPARALLELED ACCURACY AND ADAPTABILITY FOR VARIOUS DEPOSIT RETURN SYSTEMS. FEATURES LIKE THE ACO 360° DOUBLE DECK BARCODE RECOGNITION AND AI-BASED RECOGNITION, ALONG WITH CAPABILITIES LIKE WEIGHT, LIQUID, MATERIAL, COLOR, AND SHAPE DETECTION, EMPOWER OPERATORS WITH CUSTOMIZABLE SETTINGS VIA THE USER-FRIENDLY V5 PLATFORM. THIS INNOVATION FACILITATES PRECISE CONTAINER SORTING, ANTI-FRAUD FEATURES, AND PROGRAM-SPECIFIC ADJUSTMENTS, REDEFINING THE EFFICIENCY AND ADAPTABILITY OF REVERSE VENDING MACHINE TECHNOLOGY.

ACO 360 DOUBLE DECK BARCODE

RECOGNITION TECH

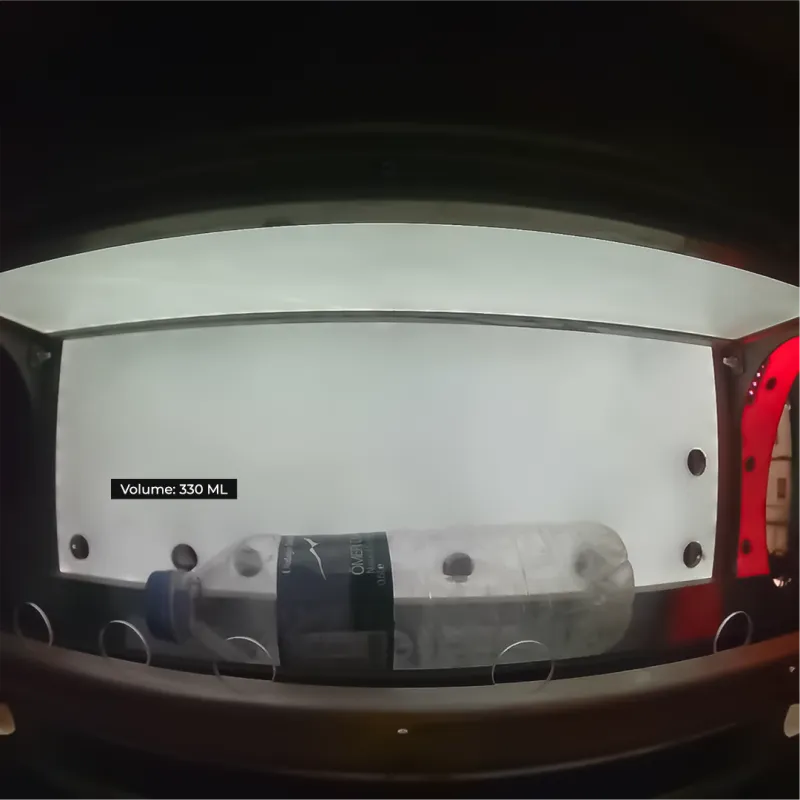

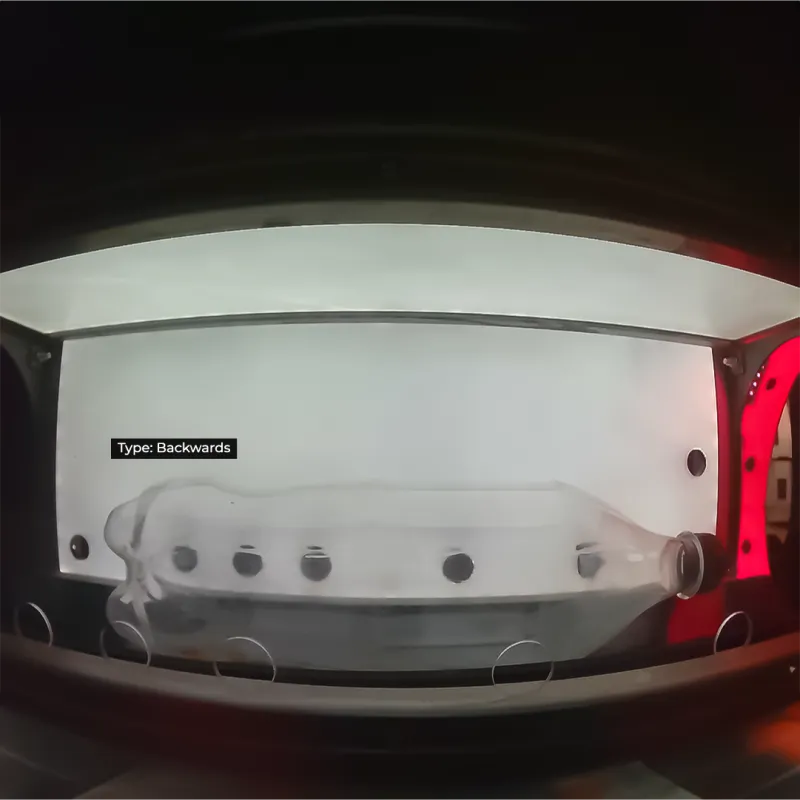

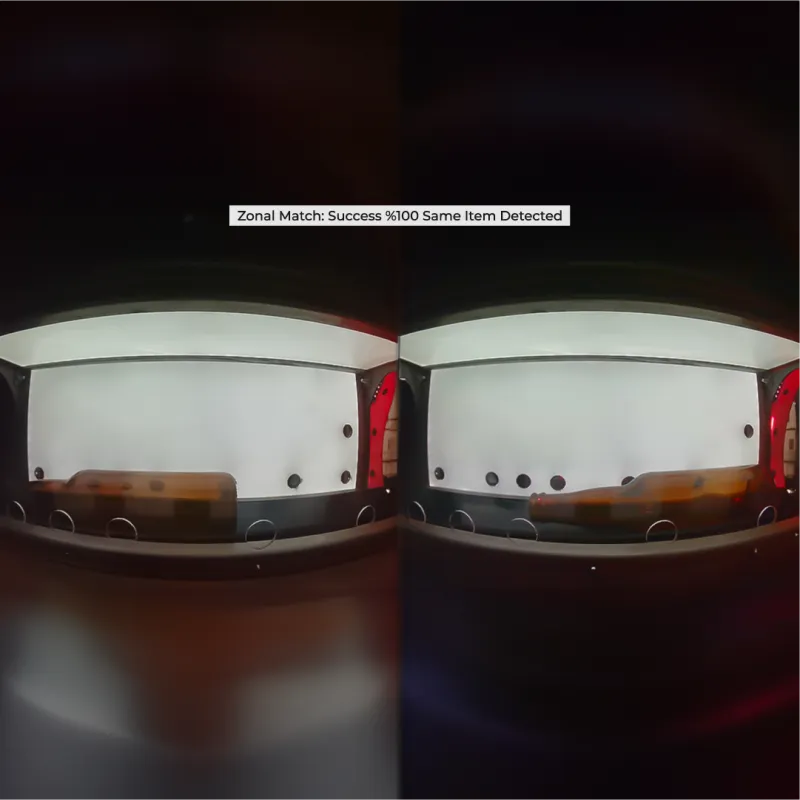

ACO AI BASED RECOGNITION TECH

WEIGHT DETECTION

LIQUID DETECTION

SENSOR BASED MATERIAL

RECOGNITION

COLOR RECOGNITION

WITH CAP OR WITHOUT

CAP DETECTION

SHAPE RECOGNITION

BOTTLE OR NOT DETECTION

VARIOUS DRS ICON RECOGNITION

ABILITY & ADAPTABILITY

ADVANCE ANTI-FRAUD FEATURE

SIZE & VOLUME DETECTION

INSERT TYPE DETECTION

BACKWARDS OR FRONTWARD

MATERIAL TYPE RECOGNITION

ZONE RECOGNITION

THE FLEXIBILITY TO CHANGE ACCEPTANCE SCENARIOS BASED ON DIFFERENT REQUIREMENTS ADDS ANOTHER LAYER OF CUSTOMIZATION, MAKING THESE MACHINES HIGHLY EFFICIENT AND ADAPTABLE TO VARIOUS DEPOSIT RETURN SYSTEM NEEDS. THIS BLEND OF SPEED, ACCURACY, AND ADAPTABILITY SETS ACO RECOGNITION TECHS APART IN THE INDUSTRY, ENHANCING THE OVERALL RECYCLING EXPERIENCE.

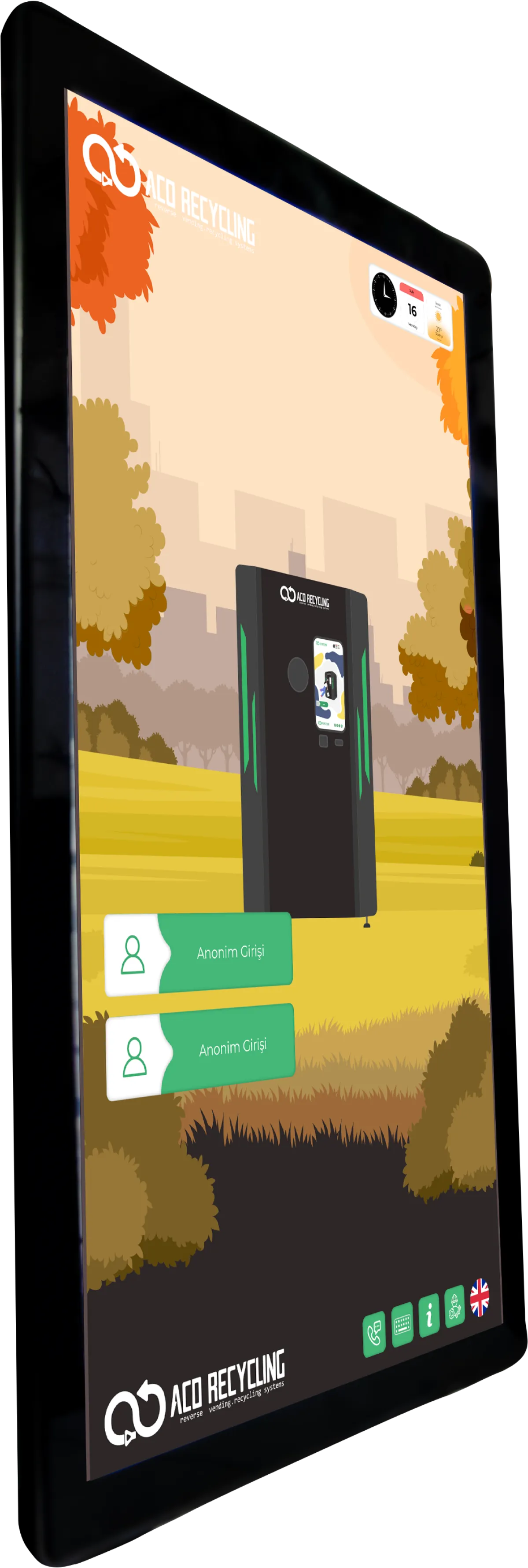

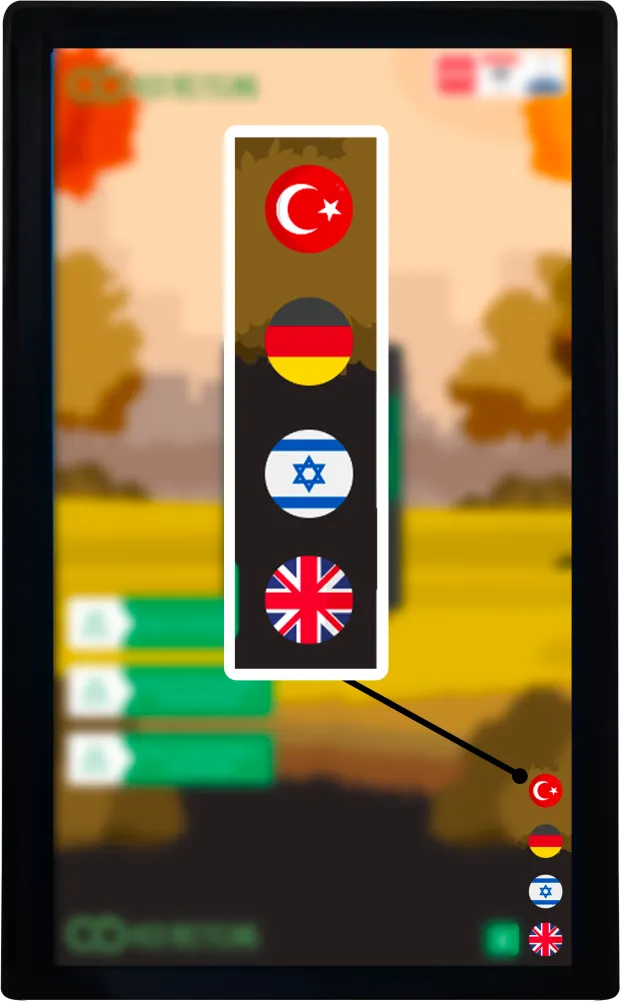

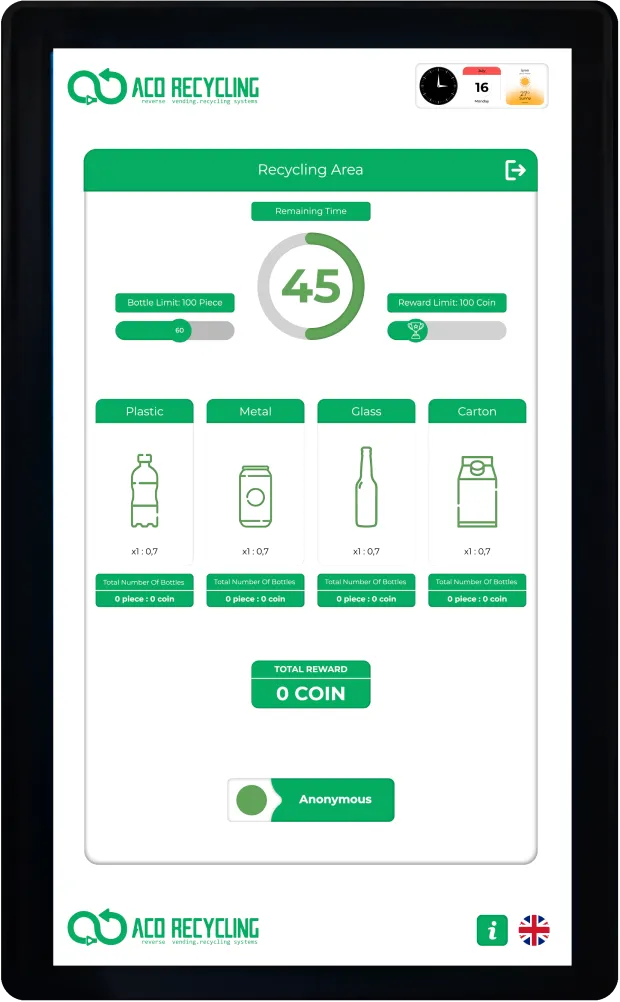

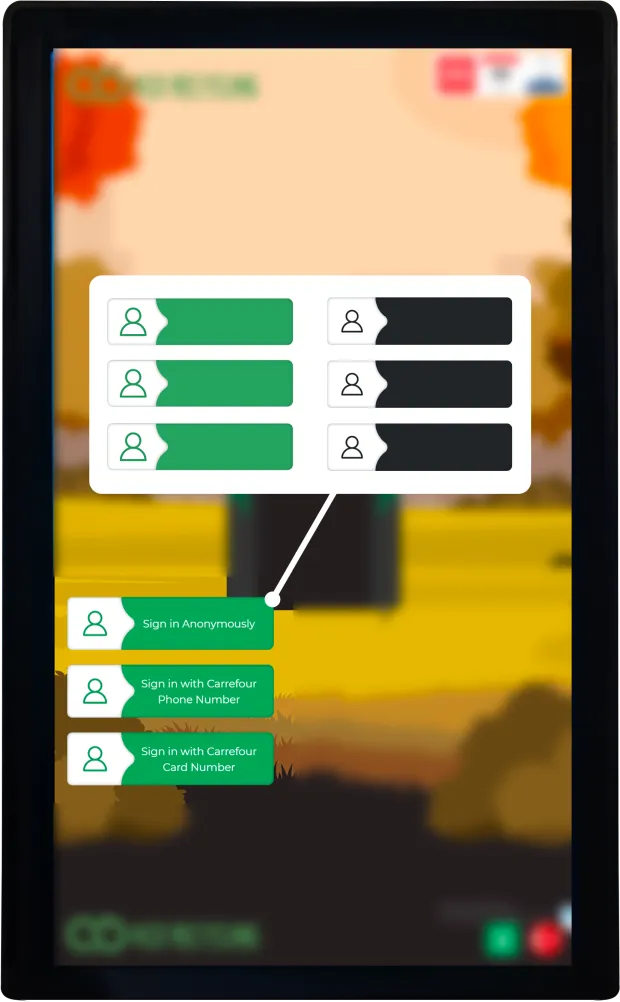

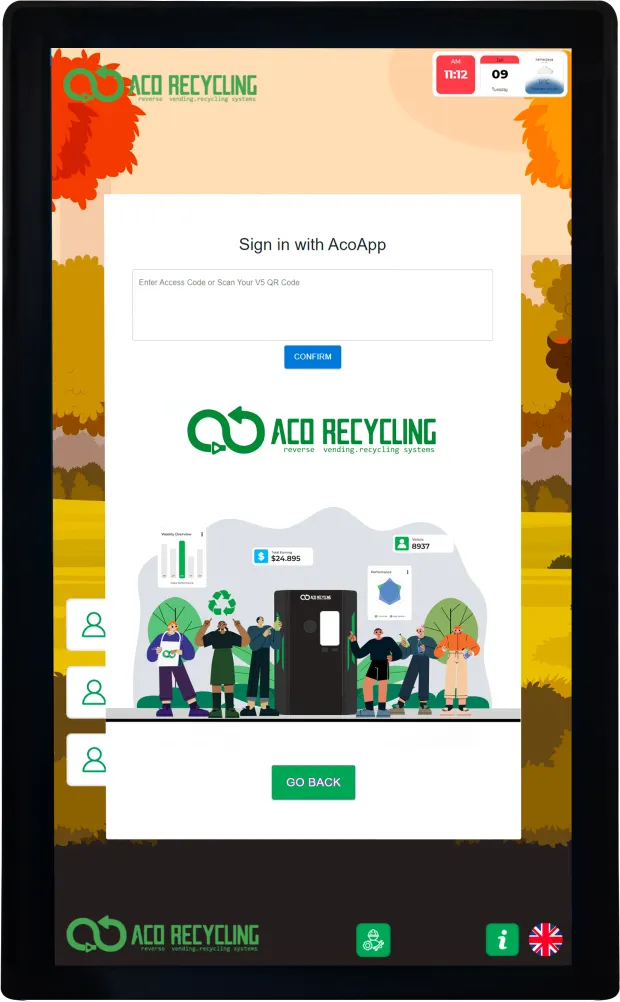

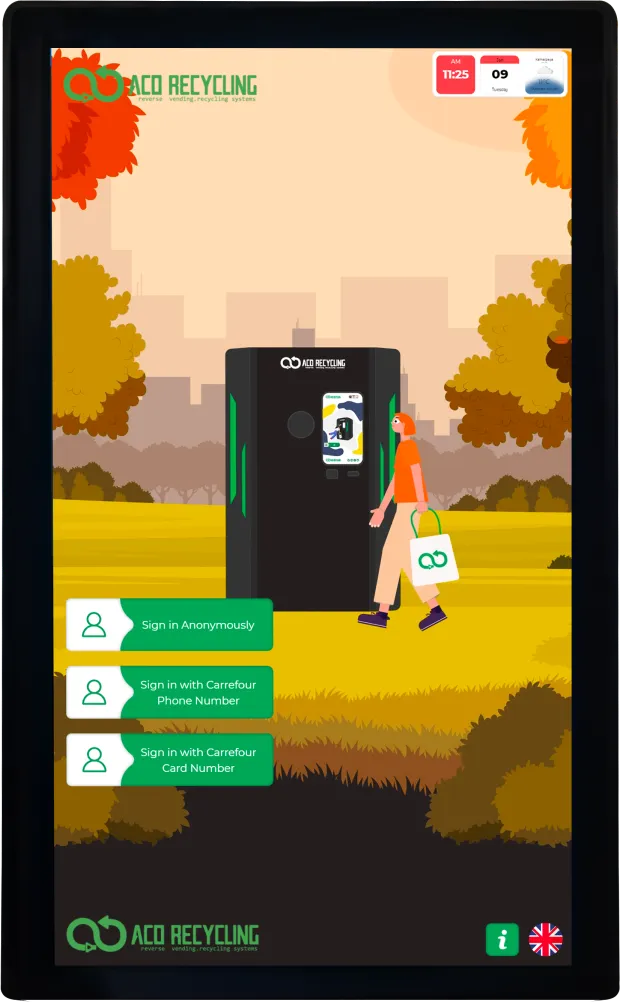

UI & DISPLAY

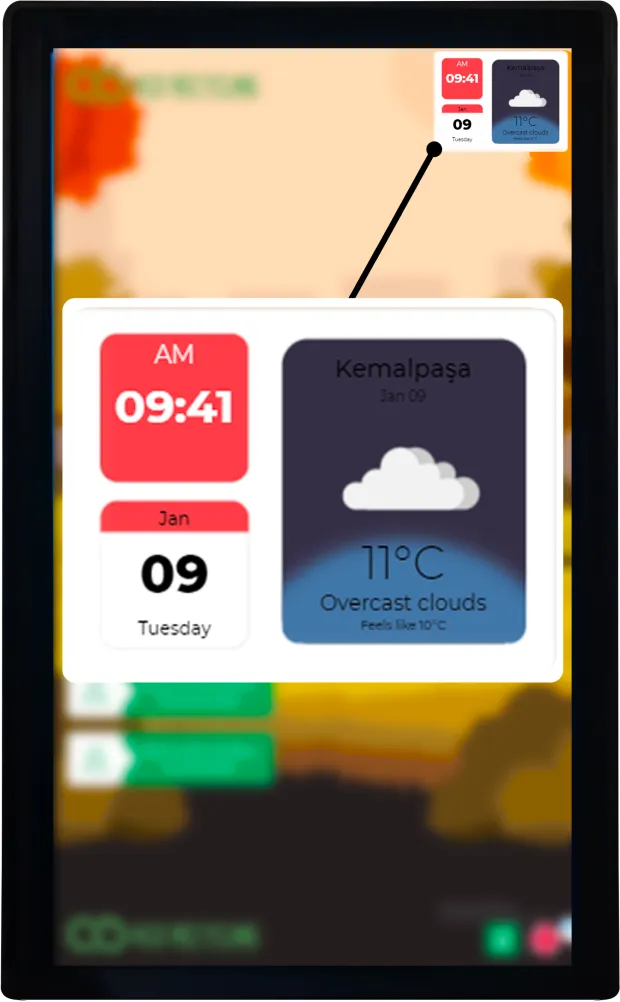

EXPERIENCE THE FUTURE OF USER INTERACTION WITH ACO RECYCLING UI & DISPLAY SCREEN, SHOWCASING THE 21.5-INCH TOUCH DISPLAY SCREEN ON ACO RECYCLING REVERSE VENDING MACHINES. THIS INTERFACE IS A BLEND OF FUNCTIONALITY AND STYLE, OFFERING MULTILINGUAL SUPPORT, INTUITIVE INSTRUCTIONS, AND DYNAMIC STANDBY MODES FEATURING ADS OR VIDEOS. IT’S DESIGNED FOR OPTIMAL USER ENGAGEMENT, FEATURING CUSTOMIZABLE THEMES, REAL-TIME WEATHER UPDATES, AND USER-FRIENDLY NAVIGATION. THE UNIQUE QR-ACCESSED UI FOR FIELD TEAMS ENHANCES OPERATIONAL EFFICIENCY, MAKING EVERY INTERACTION WITH OUR MACHINES NOT JUST A TRANSACTION, BUT A SEAMLESS, ENGAGING EXPERIENCE.

FEATURES

21.5 INCH TOUCH DISPLAY: IMMERSE IN THE LARGE, INTERACTIVE 21.5-INCH TOUCH DISPLAY, OFFERING A CLEAR AND ENGAGING USER EXPERIENCE.

MULTILINGUAL SUPPORT: OUR MACHINES CATER TO DIVERSE AUDIENCES WITH MULTILINGUAL SUPPORT, ENSURING ACCESSIBILITY FOR ALL USERS.

USER-FRIENDLY INTERFACE: NAVIGATE WITH EASE THROUGH OUR INTUITIVE, USER-FRIENDLY INTERFACE, DESIGNED FOR SIMPLICITY AND EFFICIENCY.

LOCAL TIME/DATE & WEATHER: STAY INFORMED WITH REAL-TIME LOCAL TIME, DATE, AND WEATHER UPDATES, DIRECTLY ON THE DISPLAY.

THEME CUSTOMIZATION: PERSONALIZE YOUR EXPERIENCE WITH CUSTOMIZABLE THEMES, TAILORING THE DISPLAY TO YOUR AESTHETIC PREFERENCES.

STATUS ANIMATED MESAGGES: ENGAGE WITH DYNAMIC, ANIMATED STATUS MESSAGES, PROVIDING CLEAR AND LIVELY COMMUNICATION.

FIELD TEAM UI: SPECIALIZED UI FOR FIELD TEAMS ENHANCES OPERATIONAL MANAGEMENT WITH TAILORED ACCESS AND TOOLS.

ADS: LEVERAGE THE DISPLAY FOR IMPACTFUL ADVERTISING, TURNING IDLE SCREEN TIME INTO A MARKETING OPPORTUNITY.

CHANGEABLE LOGO/BRANDING : IT’S A VERSATILE TOOL FOR BRANDING, ENSURING THAT THE MACHINES ALWAYS ALIGN WITH THE CURRENT ENVIRONMENT OR PROMOTIONAL CAMPAIGNS.

SUB-MODELS

DISCOVER THE VERSATILITY OF THE D-LINE REVERSE VENDING MACHINE AND ITS SUB-MODELS, EACH TAILORED TO SPECIFIC DEPOSIT RETURN SYSTEM NEEDS. THESE SUB-MODELS VARY BASED ON THE TYPE OF ITEMS THEY ACCEPT – BE IT PLASTIC, ALUMINUM/STEEL CANS, GLASS, OR CARTON. THEY ALSO FEATURE DIVERSE MODULES LIKE SHREDDERS, COMPACTORS, AND SPECIALIZED DROPS FOR SEGREGATION AND CRUSHING. EACH VARIANT IS DETAILED WITH ITS TOTAL ITEM CAPACITY, WEIGHT, AND UNIQUE FEATURES THAT SET IT APART. IDEAL FOR DIFFERENT USE CASES, THESE SUB-MODELS OFFER TAILORED SOLUTIONS TO SUIT A VARIETY OF OPERATIONAL REQUIREMENTS, MAKING THE D-LINE RANGE ADAPTABLE AND EFFICIENT.

REVIEW

- ACO D-LINE D1100

- ACO D-LINE D2100

- ACO D-LINE D3100

- ACO D-LINE D4100

- ACO D-LINE D5100

- ACO D-LINE D6100

K-3 5100

PROCESS SPEED

60 ITEM PROCESSING

PER MINUTE.

CAPACITY

LOCATED IN İZMİR,

TURKEY, ACO

RECYCLING’S 3,000M2

INNER CONTAINER QTY

3

ACCEPTED ITEMS

PLASTIC

![]()

GLASS

![]()

ALUMINIUM/STEEL CANS

![]()

CARTON

![]()

VOUCHER SIZE

W

H

8CM

3.14INCH

14CM

5.51INCH

FEATURES

REWARD MODELS: THERMAL PRINTER TO GIVE OUT VOUCHERS, INTEGRATION TO EXTERNAL CARD READER SYSTEM, INTEGRATION TO EXTERNAL API AND APP ONLINE REWARD MODEL INTEGRATIONS

ACO RECYCLING AI BASED PHOTO RECOGNITION TECH & ACO RECYCLING CUSTOM 360 DEGREE BARCODE RECOGNITION TECH COMBINED WITH WEIGHT RECOGNITION

OPERATING TEMPERATURE: 0 C° TO 42 C°

CONNECTIVITY: LAN OR 4G ROUTER OPTIONS

MODULS

SUB-MODELS

DISCOVER THE VERSATILITY OF THE D-LINE REVERSE VENDING MACHINE AND ITS SUB-MODELS, EACH TAILORED TO SPECIFIC DEPOSIT RETURN SYSTEM NEEDS. THESE SUB-MODELS VARY BASED ON THE TYPE OF ITEMS THEY ACCEPT – BE IT PLASTIC, ALUMINUM/STEEL CANS, GLASS, OR CARTON. THEY ALSO FEATURE DIVERSE MODULES LIKE SHREDDERS, COMPACTORS, AND SPECIALIZED DROPS FOR SEGREGATION AND CRUSHING. EACH VARIANT IS DETAILED WITH ITS TOTAL ITEM CAPACITY, WEIGHT, AND UNIQUE FEATURES THAT SET IT APART. IDEAL FOR DIFFERENT USE CASES, THESE SUB-MODELS OFFER TAILORED SOLUTIONS TO SUIT A VARIETY OF OPERATIONAL REQUIREMENTS, MAKING THE D-LINE RANGE ADAPTABLE AND EFFICIENT.

REVIEW

K-3 5100

ACCEPTED ITEMS

PLASTIC

![]()

GLASS

![]()

STEEL

![]()

CARTON

![]()

VOUCHER SIZE

W

H

8CM

3.14INCH

14CM

5.51INCH

MODULS

ONLINE V5 MONITORING

&MANAGEMENT

V5 ONLINE MONITORING & MANAGEMENT PLATFORM REPRESENTS THE PINNACLE OF TECHNOLOGY FOR REVERSE VENDING MACHINES AND DEPOSIT RETURN SOLUTIONS. IT OFFERS AN UNPARALLELED COMPREHENSIVE AND TRANSPARENT VIEW OF OPERATIONS. EVERY ACO RECYCLING REVERSE VENDING MACHINE CONNECTED TO THE V5 PLATFORM PROVIDES DETAILED INSIGHTS INTO EACH TRANSACTION, MACHINE STATUS, FULLNESS LEVELS, AND EFFICIENCY REPORTS. THIS PLATFORM IS A POWERHOUSE OF BIG DATA ANALYTICS, ENABLING COST-EFFECTIVE COLLECTION STRATEGIES AND CONTINUAL IMPROVEMENT. WITH V5, YOU’RE NOT JUST MONITORING MACHINES; YOU’RE HARNESSING THE POWER OF ADVANCED DATA TO REVOLUTIONIZE OPERATION EFFICIENCY.

AFTER SALES

AFTER-SALES SERVICE AT ACO RECYCLING IS A CORNERSTONE OF OUR OPERATIONS, ENSURING THE HIGHEST PERFORMANCE AND CONTRIBUTING TO THE PROFITABILITY OF YOUR INVESTMENT. OUR DEDICATED TEAM, ACOGURU, IS COMMITTED TO PROVIDING UNPARALLELED SUPPORT BOTH ON THE FIELD AND REMOTELY, INCLUDING A WHATSAPP HOTLINE FOR IMMEDIATE ASSISTANCE. WE OFFER ULTIMATE SUPPORT AND A COMPREHENSIVE 12-MONTH WARRANTY WITH OUR MACHINES. THIS LEVEL OF AFTER-SALES CARE IS INTEGRAL TO MAINTAINING THE EFFICIENCY AND LONGEVITY OF OUR REVERSE VENDING MACHINES, REAFFIRMING OUR COMMITMENT TO CUSTOMER SATISFACTION AND OPERATIONAL EXCELLENCE.

VINYL DESIGN

ACO RECYCLING OFFERS CUSTOMIZED BRANDING OPTIONS FOR REVERSE VENDING MACHINES THROUGH VINYL DESIGN WRAPPING. THIS FEATURE NOT ONLY ENHANCES THE MACHINE’S AESTHETIC APPEAL BUT ALSO SERVES PRACTICAL PURPOSES. IT ALLOWS FOR EFFECTIVE COMMUNICATION, LOCALIZATION, SHOWCASING OF LOGOS, AND HIGHLIGHTING OF SPONSORS. THIS VINYL WRAPPING TRANSFORMS ACO RECYCLING REVERSE VENDING MACHINES INTO A VIBRANT PART OF YOUR MARKETING STRATEGY, CREATING A MORE ENGAGING AND PERSONALIZED DEPOSIT RETURN EXPERIENCE. IT TURNS EACH MACHINE INTO A BILLBOARD, AMPLIFYING BRAND PRESENCE AND SPONSORSHIP VISIBILITY IN VARIOUS ENVIRONMENTS.

CONTACT US

GET IN TOUCH AND LET US KNOW HOW WE CAN HELP. FILL OUT THE FORM AND WE’LL BE IN TOUCH AS SOON AS POSSIBLE.

MICRO SERVICE ARCHITECTURE

ACO RECYCLING REVERSE VENDING MACHINES ARE DESIGNED WITH A MICRO SERVICE ARCHITECTURE, HARMONIZING SOFTWARE INGENUITY WITH EXTENSIVE FIELD AND USER EXPERIENCE. THIS ARCHITECTURE FACILITATES MULTI-LAYERED COMMUNICATION, ALLOWING EACH SERVICE TO OPERATE INDEPENDENTLY AS EFFICIENT MINI-TASKS. WITH MINIMAL RISK OF SOFTWARE ISSUES, EACH MICRO SERVICE IS CRAFTED BY SENIOR EXPERTS IN THEIR RESPECTIVE FIELDS, ENSURING PEAK PERFORMANCE. THIS SYSTEM EXEMPLIFIES OUR COMMITMENT TO DELIVERING ADVANCED, RELIABLE, AND HIGH-QUALITY SOFTWARE SOLUTIONS, ENHANCING THE OVERALL FUNCTIONALITY AND USER EXPERIENCE OF ACO RECYCLING REVERSE VENDING MACHINES.

MODULAR INNER

MECHANICS

THE MODULAR INNER MECHANICS OF ACO RECYCLING REVERSE VENDING MACHINES EXEMPLIFY ROBUST ENGINEERING AND CRAFTSMANSHIP. WITH TOP-LEVEL DESIGN SUPPORTED BY #TEAMACO, THESE MACHINES BOAST A MODULAR BUILD, SEGMENTED BY A ZONE SYSTEM FOR EASY ACCESS. THIS DESIGN SIMPLIFIES MAINTENANCE, CLEANING, AND PART REPLACEMENT, REFLECTING OUR DEEP CONSIDERATION FOR FUTURE USABILITY. EACH MACHINE IS AN EMBODIMENT OF SIMPLICITY AND EFFICIENCY, ENSURING LONGEVITY AND RELIABILITY IN DEPOSIT RETURN OPERATIONS.

EMPTYING &

COLLECTION

ACO RECYCLING’S REVERSE VENDING MACHINES EMPHASIZES SIMPLICITY AND EFFICIENCY IN DEPOSIT RETURN SYSTEMS. OUR MACHINES FEATURE SPECIALLY DESIGNED INNER CONTAINERS TO FACILITATE EASY EMPTYING, WITH OPTIONS TO USE BIG BAGS FOR ADDED CONVENIENCE. THE SUGGESTED COLLECTION STRATEGY INVOLVES HAVING A RESERVE FOR EACH CONTAINER, ENSURING SEAMLESS REPLACEMENT AND SECURE STORAGE OF COLLECTED MATERIALS. THIS SYSTEM OFFERS FLEXIBILITY FOR SMALLER OPERATIONS, ALLOWING FOR EFFICIENT HANDLING WITHOUT A RESERVE SYSTEM, OR BY USING BAGS WITHIN THE INNER. THE REAL GAME-CHANGER IS OUR V5 PLATFORM, ALLOWING EACH COLLECTION PERSONNEL TO HAVE A CUSTOM ID. THIS FEATURE ENABLES OPERATORS TO MONITOR PICK-UP TIMES, ENHANCING OPERATIONAL EFFICIENCY. THEY CAN ALSO TRACK WHICH STAFF MEMBER SERVICED WHICH MACHINE, AND WHEN, PROVIDING A COMPREHENSIVE VIEW OF THE COLLECTION PROCESS AND ENSURING TOP-NOTCH MANAGEMENT OF DEPOSIT RETURN SYSTEM OPERATIONS.

GLOBALLY

DEPLOYABLE

ACO RECYCLING’S MACHINES ARE ‘GLOBALLY DEPLOYABLE,’ DESIGNED FOR SEAMLESS ADAPTABILITY ACROSS ALL DEPOSIT RETURN SYSTEMS. THEY FEATURE EXTENSIVE LOCALIZATION CAPABILITIES, INCLUDING MULTI-LANGUAGE SUPPORT, ENSURING RELEVANCE IN DIVERSE MARKETS. OUR COMPREHENSIVE INSTALLATION SERVICES, BACKED BY LOCAL TECHNICAL TEAM TRAINING, FACILITATE EFFICIENT SETUP AND MAINTENANCE. WITH AN INTERNATIONAL SERVICE NETWORK AND ACOGURU SUPPORT, WE GUARANTEE RAPID RESPONSE TIMES AND EFFECTIVE SOLUTIONS, MAKING OUR MACHINES IDEAL FOR WORLDWIDE DEPLOYMENT IN VARIOUS DEPOSIT RETURN SYSTEM SCENARIOS.